Choosing the Right Steel Grating: Key Factors to Consider

In industrial, commercial, and architectural settings, steel grating is more than just a functional flooring or drainage solution, it’s a structural element that must meet demanding standards. Whether you’re specifying grating for a catwalk, mezzanine, trench cover or stair tread, understanding the nuances of grating selection is vital for safety, durability, and project success.

Understand the Application Environment

The first step in selecting steel grating is to consider the environment where it will be used. Will it be exposed to heavy foot traffic, vehicle loads, chemicals, or weather extremes? Galvanised steel suits most outdoor environments thanks to its corrosion resistance, while stainless steel may be preferred for more aggressive conditions, such as food processing plants or marine facilities.

Select the Right Load-Bearing Capacity

Grating panels come with load ratings that vary depending on bar thickness, spacing, and material type. Misjudging load-bearing capacity can result in deflection, safety hazards, or premature failure. Structural engineers should be consulted where exacting performance criteria are involved, especially for elevated platforms or high-traffic zones.

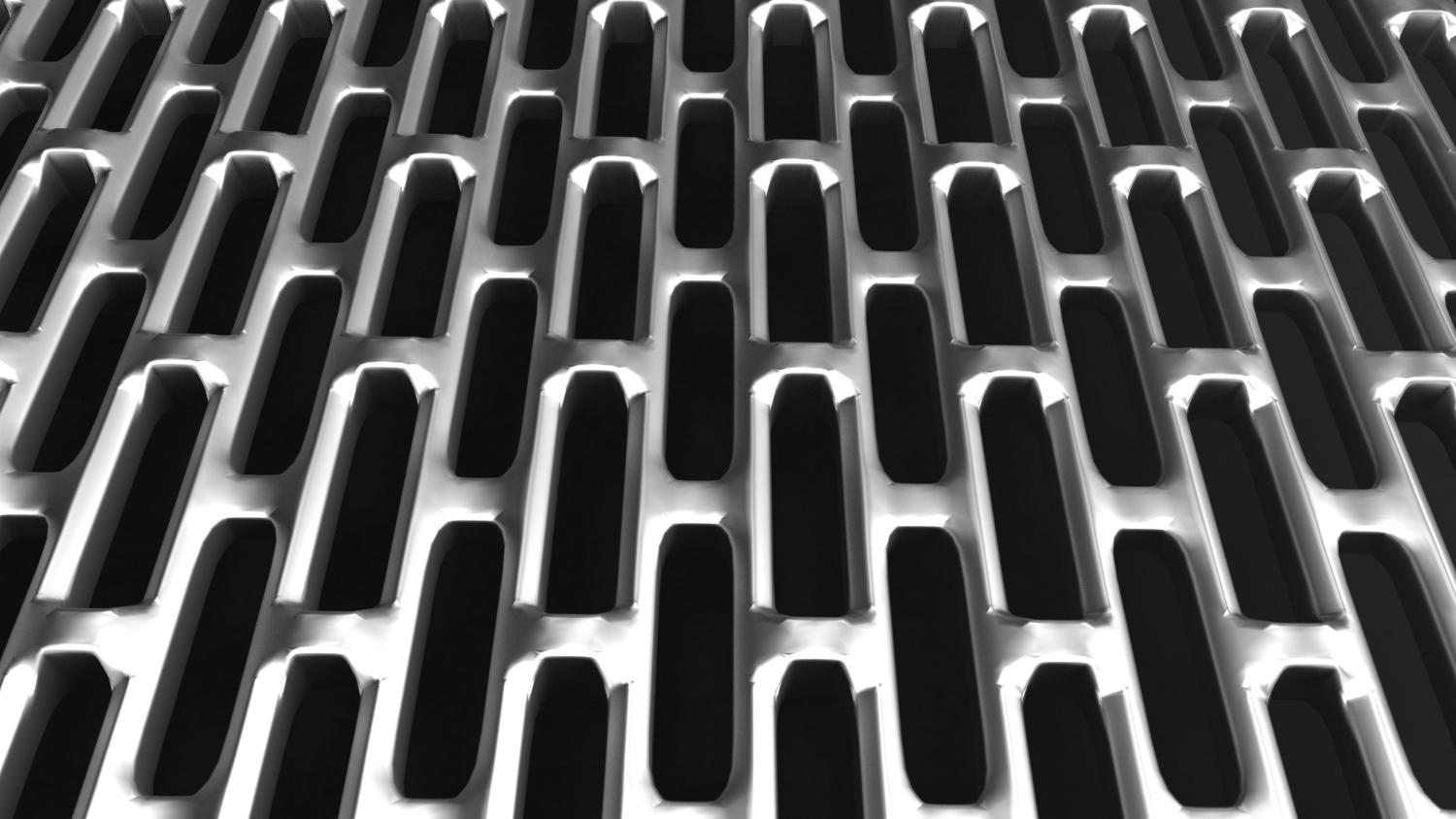

Consider Grating Type and Surface

There are different types of steel grating: welded, press-locked, swaged, and riveted—each with advantages. Welded grating, the most common, is known for strength and rigidity. Press-locked variants offer a smoother appearance with strong lateral stability. Surface type also matters: plain top bars are easier to clean, while serrated bars improve slip resistance, important in oily or wet conditions.

Account for Span and Support Needs

Proper grating design takes into account span direction and support structures. Bar direction (load bar vs. crossbar) influences how loads are transferred. Panels should always be installed with load bars spanning between supports, not parallel to them. Inadequate support can lead to instability or increased wear.

Customisation and Sizing Options

Standard sizes may not fit every project. Many manufacturers offer custom cutting, notching, or banding to accommodate unique configurations. If aesthetics are a consideration, such as in architectural façades, ensure grating can be powder-coated or finished to your specifications without compromising performance.

Compliance and Safety Standards

Depending on the jurisdiction and use case, steel grating may need to comply with specific building codes or safety standards. These might cover spacing between bars to prevent object fall-through, slip resistance ratings, or fire resistance. Ensuring compliance from the outset avoids costly retrofitting later.

Choosing the correct steel grating for industrial application is a balance of engineering, environment, and application-specific requirements. Factoring in load ratings, material choice, and safety compliance ensures you select a solution that performs reliably under pressure, literally and figuratively.