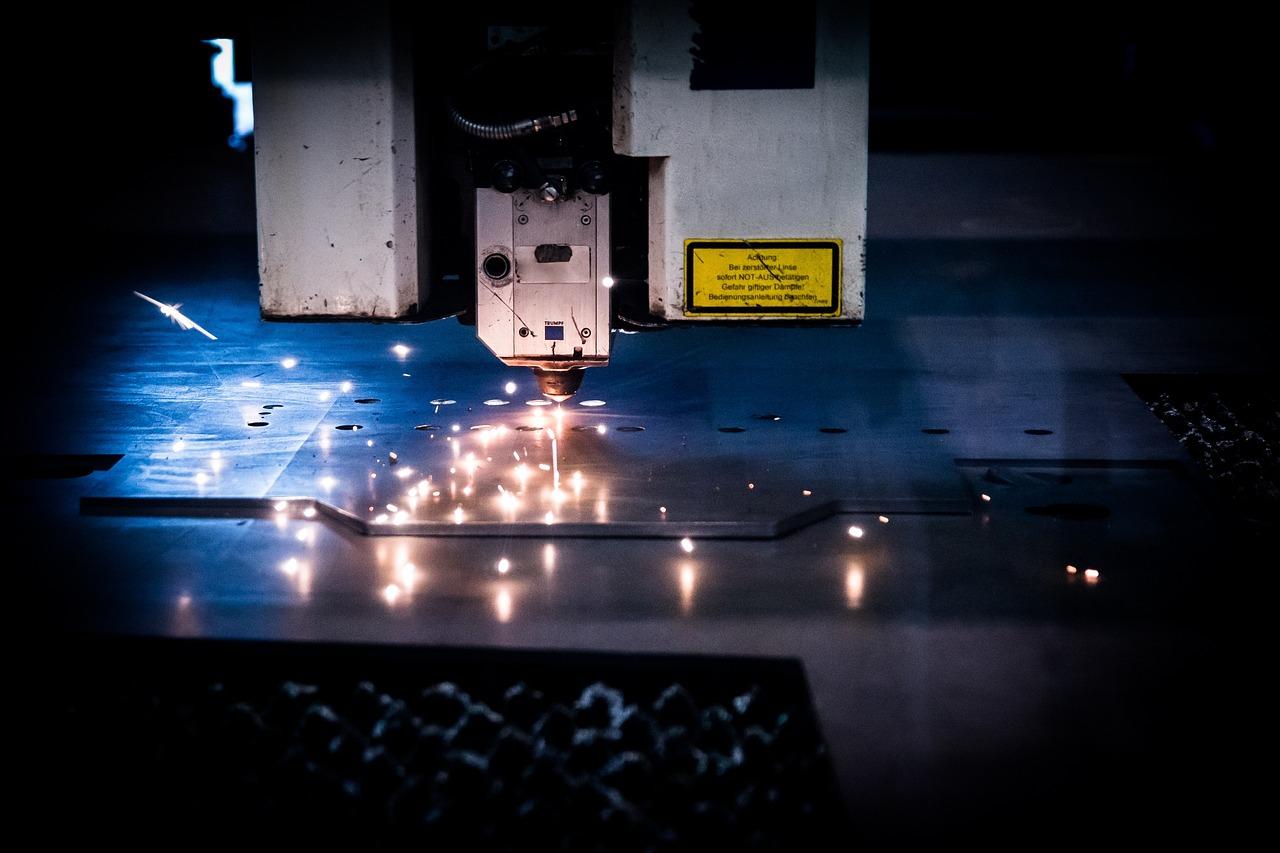

Laser Metal Cutting: Precision Engineering for Modern Industries

In advanced manufacturing, precision and efficiency are non-negotiable. Laser metal cutting has revolutionized the way industries shape metals, allowing for intricate designs, minimal material waste, and faster production times. From automotive and aerospace to electronics and signage, laser metal cutting meets the highest standards for accuracy and consistency.

What Is Laser Metal Cutting?

Laser metal cutting is a thermal process where a high-powered laser beam melts, burns, or vaporizes the material along a programmed path. Guided by computer numerical control (CNC) systems, the laser can cut metals of varying thicknesses with incredible precision, leaving smooth, burr-free edges that require little to no post-processing.

Benefits of Laser Metal Cutting

There are many advantages to choosing laser metal cutting over traditional fabrication methods:

- Exceptional Accuracy: CNC guidance allows intricate shapes and complex patterns to be cut with tolerances measured in microns.

- Material Efficiency: With minimal kerf and reduced offcuts, laser metal cutting uses less material — helping control costs and reduce waste.

- Speed and Scalability: Faster than mechanical cutters, laser machines can cut both one-off prototypes and large production runs with consistent quality.

- Smooth Finishes: Parts cut by laser often need no further finishing, allowing for immediate use or assembly.

Wide Range of Applications

Because of its flexibility and accuracy, laser metal cutting is commonly used in diverse industries. Automotive companies cut components like brackets and enclosures to exact shapes. Architectural fabricators produce decorative panels and structural elements for modern buildings. Even electronics companies use laser-cut metals for device housings and heat sinks.

Additionally, laser cutting is highly effective on a broad range of metals — including mild steel, stainless steel, aluminum, and even more reflective metals — making it suitable for nearly any project.

Considerations When Choosing a Provider

When selecting a company to perform laser metal cutting, it’s important to look at:

- Equipment capabilities: Fiber lasers offer faster cutting speeds and better energy efficiency, especially for thinner metals.

- Material expertise: An experienced shop will recommend the best laser settings for different alloys and thicknesses.

- Quality control: Look for rigorous inspection processes that ensure consistent cut quality across every part produced.

Final Thoughts

As a fast, precise, and cost-effective fabrication method, laser metal cutting has earned its place as a cornerstone of modern engineering. Companies that invest in this technology gain a competitive advantage — delivering high-quality components quickly and reliably for their customers.